ACME ana ürünleri, lazer tüp kesme makineleri ve lazer sac kesme makineleri, dünya çapında 60 ülke ve bölgede iyi satılmaktadır. Satış bölgelerimizin dağılımı aşağıdadır. En yakın Bölge Müdürünüzle iletişime geçmeye hoş geldiniz.

Sanayi

Zaman

Bölge

Plazma kesme, testere kesme, manuel oksijen kesme vb. gibi kullandığımız geleneksel işleme yöntemleri, zayıf kesme hassasiyetine sahiptir ve bu da dengesiz ürün kalitesine neden olur.

Çalışma ortamı, düzeltme baskısıyla karşı karşıya kalarak, çevre koruma gereksinimlerinin ötesinde ciddi şekilde kirlenmiştir. İşçilik maliyeti yüksek, üretim verimliliği düşük ve pazar talebini karşılayamıyor.

Application in long workpiece

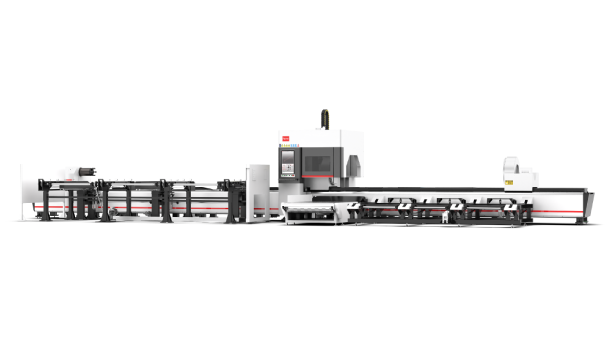

Laser cutting has small thermal deformation and is more effective for slender work-pieces requiring straightness. The "micro-joint" function of machine can be used to effectively control the straightness of the work-piece.

Three-chuck clamping can achieve zero tail cutting and reduce material waste. Strong clamping force reduces the fluctuation range of tubes, which can effectively reduce processing errors and improve processing accuracy.

Application in sheets and tubes with more holes

Using laser cutting directly, eliminating the drilling process and improving labor production efficiency.

For workpieces with more holes, the powerful software function can be used to accurately locate the hole position, reducing the cost of drilling templates, which not only improves production efficiency, but also the product accuracy.

ACME Laser original static cutting technology has more obvious cutting advantages for complex cutting patterns.

Application in cutting irregular patterns and tubes

Laser cutting machine can accurately cut irregular patterns, improve the accuracy and efficiency of cutting parts. Non-closed tubes such as I-beams, channel steel, angle steels and irregular profiles can be cut with excellent cutting sections and high precision.

Combined with modern CNC machine tools, the fiber laser cutting machine has the characteristics of high cutting precision, good controllability, simple procedures, material saving and less pollution.

Good cutting of hard materials with high hardness, high melting point and extremely brittle and difficult to machine. Because laser cutting is non-contact processing, there is no mechanical force.

info@acmelaser.com

+86 13863469522

We will contact you at the first time. If the enquiry is urgent, feel free to call! To get the final price, please fill in all detailed fields so that we can send you a detailed quotation according to your requirements and budget.

Director:

sally

Email:

info@acmelaser.com

WhatsApp:

+86 13863469522